Egg segmentation and sizing is a computer vision process used to automatically detect eggs in images or video, isolate them from the background, and determine key physical properties such as size, shape, and estimated weight. Using image analysis, it identifies each egg and extracts features like length and width, allowing for precise measurement and classification.

This technology forms the basis of intelligent grading and inspection systems, replacing manual processes that are prone to error and inefficiency.

Advanced Computer Vision for Precise Egg Segmentation and Automated Sizing

Egg processing has traditionally relied on manual inspection for grading and sizing — an approach that is slow, inconsistent, and costly. This project leverages cutting-edge computer vision and deep learning technologies to transform egg processing into a fully automated, high-precision operation.

By developing robust image segmentation algorithms, individual eggs can be accurately isolated from complex backgrounds and clustered groups, regardless of lighting or surface variability. Coupled with intelligent sizing models, this technology enables real-time classification of eggs into standardized size categories with unmatched speed and accuracy.

Importance and Applications

Accurate egg segmentation and sizing play a vital role in:

- Automated Grading: Sorting eggs into standard size categories (S, M, L, XL) for packaging and pricing.

- Weight Estimation: Predicting egg weight based on dimensions without using physical scales.

- Quality Control: Detecting deformations, or undersized eggs early in the process.

- Inventory & Counting: Combining with segmentation systems to track production volumes in real time.

Industries benefiting include poultry farms, egg packaging units, food processors, and automated retail logistics.

Challenges in Egg Segmentation and Sizing

Despite its importance, several challenges exist:

- Lighting Variations: Shadows and reflections can interfere with image clarity and affect segmentation accuracy.

- Egg Overlap: Eggs touching or overlapping each other are harder to segment individually.

- Shape Irregularities: Natural variation in egg shapes requires adaptive models rather than rigid templates.

- Calibration Errors: Without proper scaling, pixel-based measurements can lead to inaccurate sizing.

- Speed and Efficiency: Real-time processing is critical in high-throughput environments like conveyor lines.

These challenges demand a robust and flexible approach to ensure high accuracy and reliability.

Our AI Solution

Our AI-powered Egg Segmentation and Sizing system brings speed and accuracy to the forefront of egg processing operations. It enables:

- Real-time instance segmentation to isolate each egg—even when overlapped

- Size classification (small, medium, large) using mask-based measurement

- Seamless integration with conveyor belts, robotic arms, or sorting mechanisms

How Does It Work?

We address these challenges through an AI-powered pipeline combining traditional image processing and deep learning:

Input Processing

- Controlled environment: Eggs are placed on a uniform background (e.g., a flat surface) with consistent lighting to minimize shadows and reflections.

- Multi-view options: Some systems use top and front views to reduce shape distortion, while advanced methods rely on single-view metrology with reference markers.

Preprocessing

- Color space conversion: Transform RGB to HSV or Lab to isolate the egg from the background based on hue or luminance channels.

- Noise reduction: Apply blur filters or histogram equalization to smooth the image and improve segmentation, especially under multimodal lighting

Segmentation

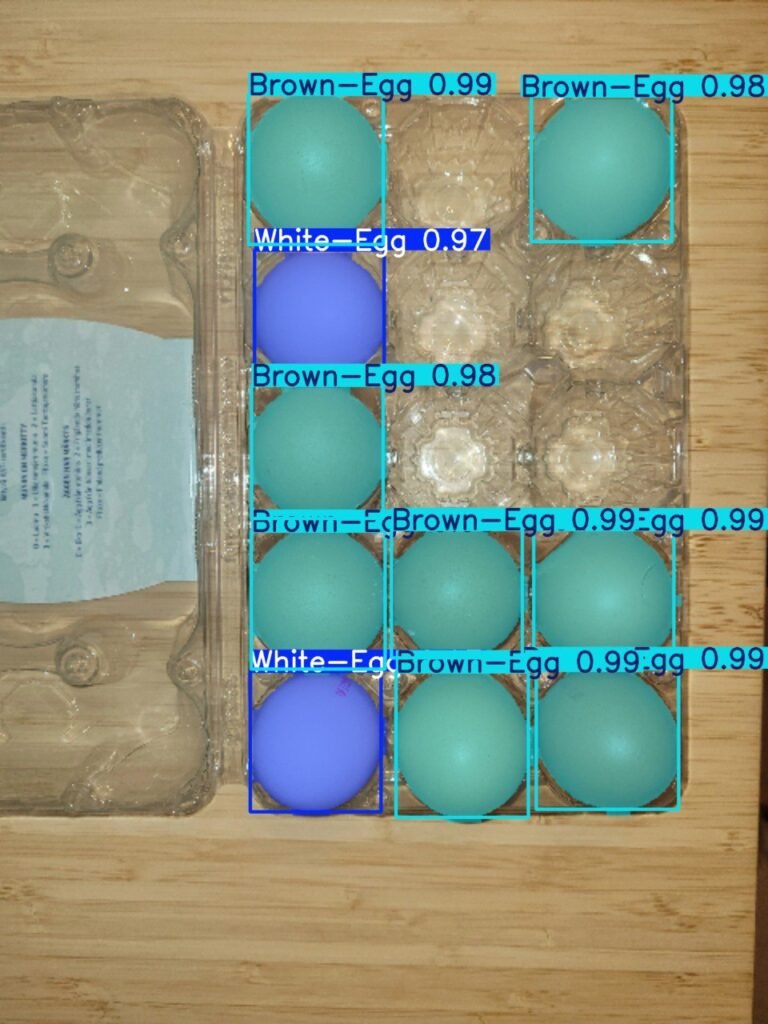

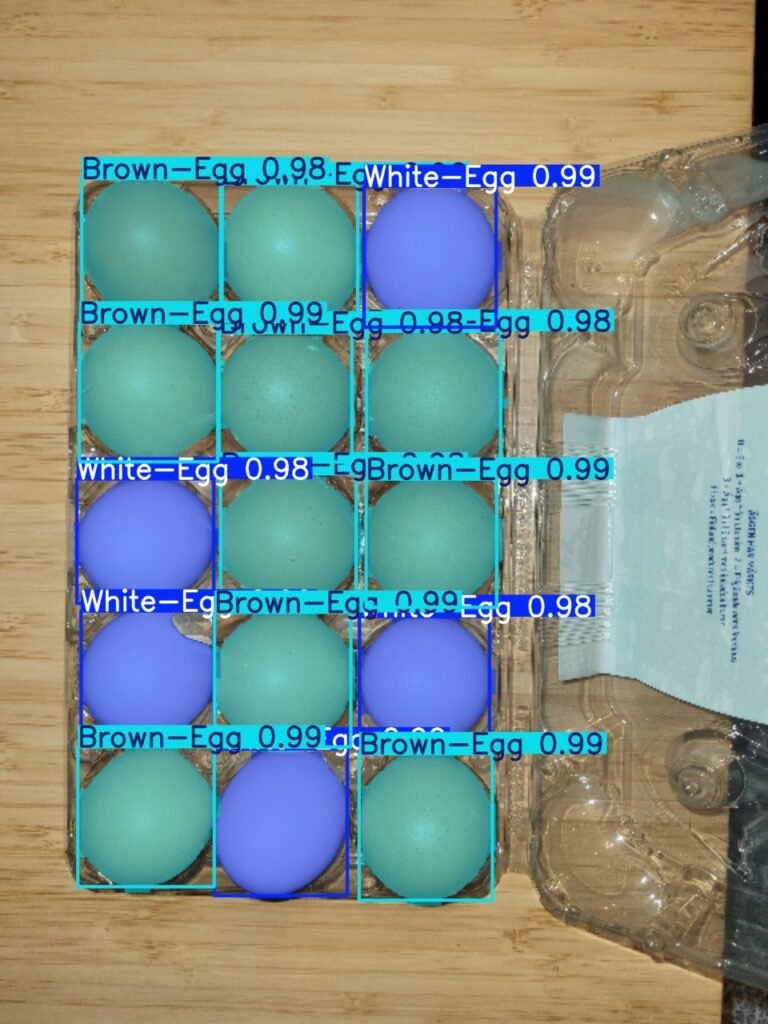

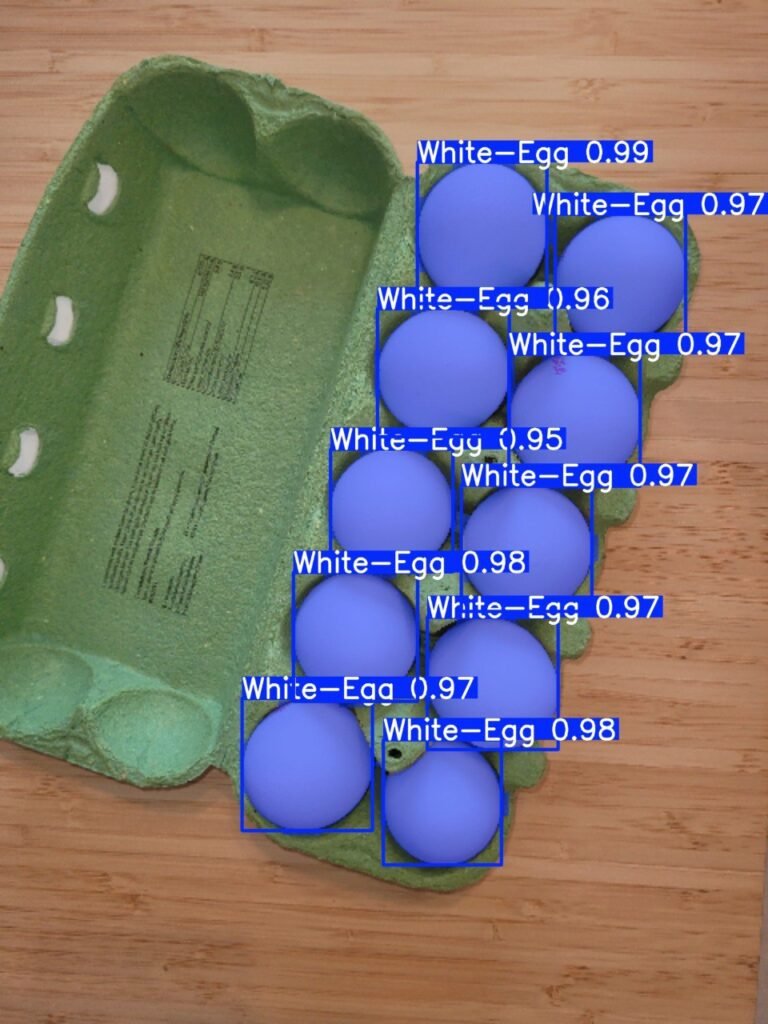

The segmentation engine employs a fine-tuned YOLO model trained on a custom annotated egg dataset. It detects eggs by dividing each input image into a grid and predicting bounding boxes along with class probabilities for each cell.

Key outputs include:

- Bounding box coordinates tightly enclosing each egg.

- Confidence scores representing the probability that the detected object is an egg.

- Classification of detected eggs by shell color (white or brown).

Segmentation masks can also be generated to precisely isolate the egg shape for further analysis.

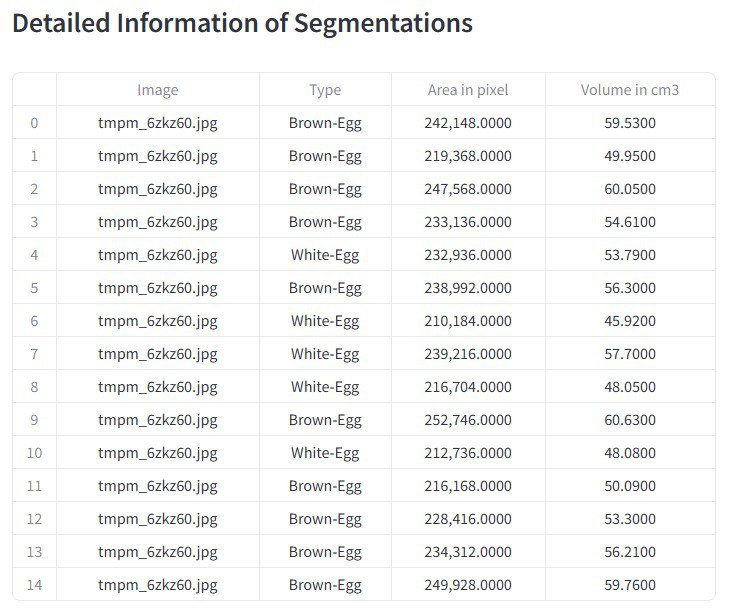

Size Measurement

- Calibrate pixel-to-mm scale: Use reference objects or vanishing-point geometry (single-view metrology) for accurate real-world measurementsSize Measurement and Weight Estimation.

- Measure axes: Calculate major (length) and minor (width) axes in millimeters.

- Accuracy: Systems typically achieve sub-1 mm error, with R² > 95 versus manual caliper measurements.

Counting Process

Post-filtered eggs are counted individually, with separate tallies maintained for white and brown eggs. For video streams, the system aggregates counts per frame, enabling real-time monitoring of production lines or batch analysis over time.

Output Visualization and Demo

Detected eggs are visually highlighted by overlaying bounding boxes and segmentation contours on the input images or video frames. Confidence scores and classification labels can be optionally displayed to communicate detection certainty and egg types. Also, the egg sizes are specified in the final output.

Real-World Example:

Imagine a mid-sized egg farm upgrading to a vision-based system. With a simple overhead camera and our deployed model, they now:

- Segment hundreds of eggs per minute

- Categorize them instantly for packing

- Route them automatically via size-based actuators

This led to:

- 40% reduction in labor costs

- 25% increase in packaging speed

- Improved compliance with retail grading standards

Dataset

The custom dataset used to train and validate the egg segmentation model is also available through the GitHub repository. It contains:

- Annotated images of eggs under different lighting and backgrounds.

- Bounding box labels required for supervised learning.

- Diverse samples to ensure model robustness.

Using this dataset, you can retrain the model or extend it to new scenarios.

More about the dataset: Egg Instance Segmentation Dataset

Code

All the source code for the Deep Egg Detection and Counter project is openly available on GitHub. The repository includes:

- Model training and evaluation scripts

- Inference code to run egg detection on images and videos

- Instructions for setting up the environment and dependencies

- Examples to help you get started quickly

Explore the code here:

Demo

Want to see the Deep Egg Segmentation and Sizing in action? Try out the live demo where you can upload your own images and watch the model detect and count eggs instantly.

👉Live Demo on: Hugging Face Spaces