Revolutionizing Egg Processing with Computer Vision

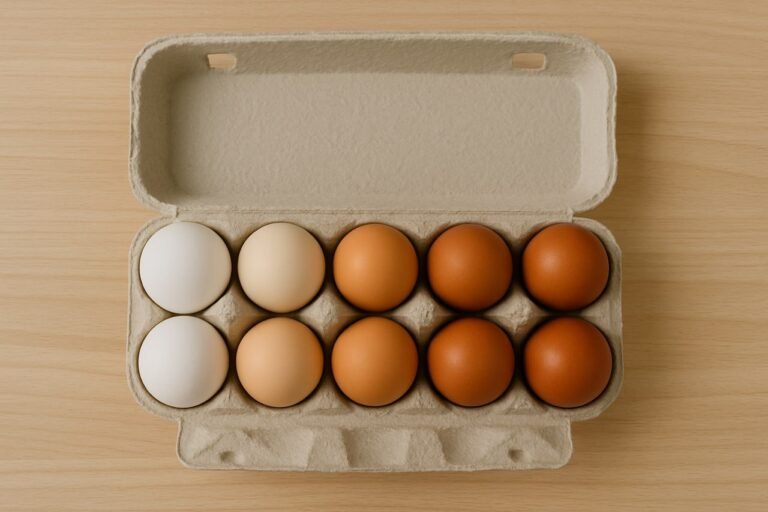

The egg industry is a critical segment of agriculture, supplying billions of eggs worldwide for consumption and further processing. Managing such vast quantities efficiently demands precision and speed, especially in tasks like egg detection, counting, color separation, and grading. Traditionally, these tasks have relied heavily on manual labor or rudimentary mechanical systems, which introduce several limitations including human error, inconsistent accuracy, and slower throughput.

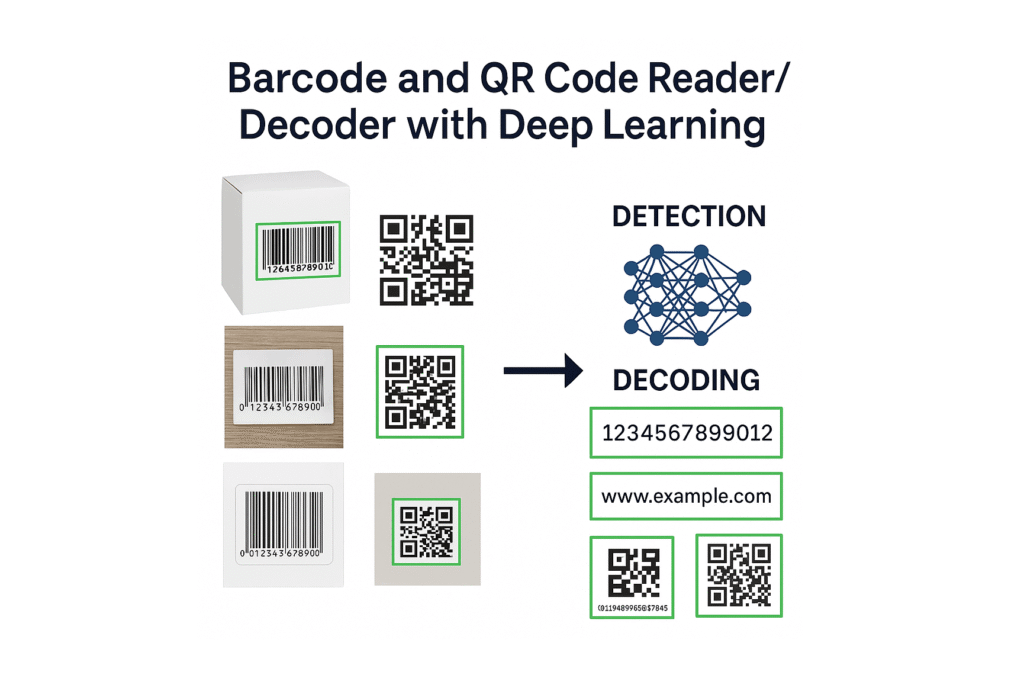

Enter computer vision — a transformative technology that leverages artificial intelligence and deep learning to enable machines to “see,” analyze, and understand visual data. By integrating computer vision into egg processing workflows, the industry can achieve unprecedented levels of automation, accuracy, and operational efficiency.

Industry Use Case: Enhancing Efficiency and Accuracy in Egg Production

Egg production and processing facilities handle immense volumes of eggs daily, from collection and sorting to packaging and shipment. In these environments, accurate counting and detection of eggs are not just operational tasks; they are essential for maintaining supply chain integrity, optimizing production efficiency, and ensuring product quality.

Challenges Faced by the Industry

- High Throughput Environments: Modern facilities process thousands of eggs per hour. Manual counting or inspection becomes impractical, time-consuming, and prone to human error.

- Variability in Egg Appearance: Eggs differ in size, color, texture, and cleanliness, which complicates automated detection.

- Overlapping and Occlusion: Eggs often appear stacked or overlapping on trays and conveyors, making counting more challenging.

- Dynamic Lighting and Backgrounds: Production lines can have inconsistent lighting or complex backgrounds that hinder traditional sensor-based detection methods.

- Labor-Intensive Processes: Manual counting requires significant workforce allocation, increasing operational costs and the risk of fatigue-induced errors.

How Our Solution Addresses These Issues

The Deep Egg Detection and Counter system leverages advanced AI-powered computer vision to overcome these challenges by delivering:

- Consistent and Accurate Counting: Automatically detects and counts eggs, even in overlapping or cluttered arrangements, minimizing miscounts and inventory discrepancies.

- Egg Classification and Separation: Separating different types and colors of eggs are done in our solution making possible to sort eggs automatically.

- Real-Time Processing: Enables on-the-fly monitoring on conveyor belts and packing stations, allowing immediate response to production line issues.

- Adaptability: Performs reliably under variable lighting conditions and with diverse egg appearances, increasing robustness compared to traditional systems.

- Labor Savings and Cost Reduction: Automates repetitive tasks, freeing human operators to focus on higher-level quality control and process management.

- Improved Traceability and Data Analytics: Digital records of counts and inspections support inventory management and quality audits.

Why This Matters for Egg Industries

Egg factories and poultry farms can greatly benefit from automating egg detection and counting. The technology streamlines inventory management, reduces wastage, and improves operational oversight. With increasing demand and the need for precise tracking, ML-based solutions like this are shaping the future of agricultural technology.

Our AI Solution

The Deep Egg Detection and Counter system is built on a carefully designed pipeline combining state-of-the-art object detection with practical post-processing techniques to deliver accurate egg detection, classification and counts from images and videos.

How Does It Work?

Input Processing

The system accepts images or video streams as input. Videos are processed frame-by-frame, enabling real-time or batch analysis. Input data can come from various sources such as surveillance cameras in farms, conveyor belt cameras in production lines, or manually captured photos.

Preprocessing

Before feeding the data to the model, the images or video frames undergo preprocessing steps such as resizing, normalization, and color space adjustment to ensure consistency. This step helps the model handle different resolutions and lighting conditions more effectively.

Deep Learning-based Object Detection

The core detection engine is based on YOLO model, a fast and accurate deep learning model designed for real-time object detection. Our model is fine-tuned on a custom dataset of annotated egg images, available HERE, allowing it to learn the unique features and shapes of eggs under various conditions.

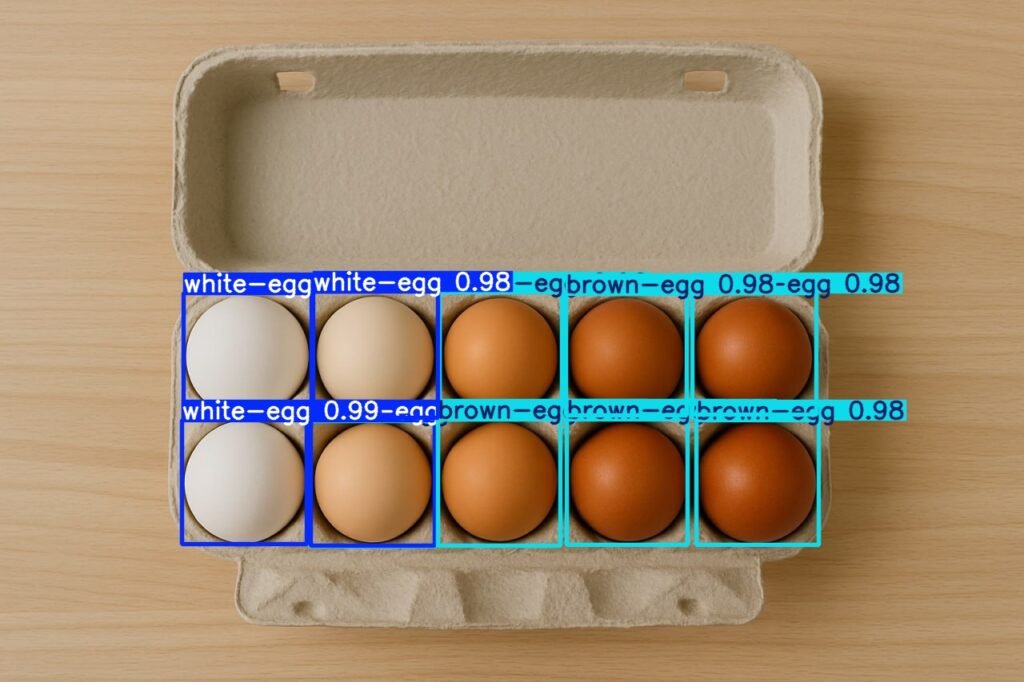

Our model works by dividing the input image into a grid and predicting bounding boxes and class probabilities for each grid cell. The model outputs:

- Coordinates of bounding boxes tightly enclosing each detected egg.

- Confidence scores indicating the likelihood that a detected object is indeed an egg.

- White and brown egg classification results.

Postprocessing and Filtering

To refine the detection results, postprocessing algorithms filter out overlapping bounding boxes using Non-Maximum Suppression (NMS). This ensures each egg is counted once, avoiding duplicates caused by overlapping detections. Thresholding based on confidence scores is applied to eliminate false positives, balancing precision and recall.

Counting Process

After filtering, the remaining bounding boxes are counted. The number of brown and white eggs as well total number of eggs will be counted automatically. For videos, the system aggregates counts per frame, which can be used for time-based analysis or monitoring.

Output Visualization and Demo

Detected eggs are highlighted by drawing bounding boxes directly on the input image or video frames. Confidence scores are optionally displayed to indicate detection certainty.

Dataset

The custom dataset used to train and validate the egg detection model is also available through the GitHub repository. It contains:

- Annotated images of eggs under different lighting and backgrounds

- Bounding box labels required for supervised learning

- Diverse samples to ensure model robustness

Using this dataset, you can retrain the model or extend it to new scenarios.

More about the dataset: Egg Detection Dataset

Code

All the source code for the Deep Egg Detection and Counter project is openly available on GitHub. The repository includes:

- Model training and evaluation scripts

- Inference code to run egg detection on images and videos

- Instructions for setting up the environment and dependencies

- Examples to help you get started quickly

Explore the code here:

Demo

Want to see the Deep Egg Detection and Counter in action? Try out the live demo where you can upload your own images and watch the model detect and count eggs instantly.

👉Live Demo on: Hugging Face Spaces