In modern manufacturing and packaging operations, accurate detection and real-time counting of products such as cans, bottles, tubes, cartons and jars is no longer a luxury, it’s a necessity. With rising automation demands and quality control standards, manufacturers need solutions that are reliable, fast and scalable. That’s where PackDet comes in.

Why Automatic Package Detection Matters

Consider a typical beverage or consumer-goods production line: hundreds or thousands of items traverse a conveyor belt every minute. Manually monitoring counts, spotting missing items or mis-categorized packages is inefficient and error-prone. Mis-counts lead to inventory discrepancy, packaging cost overruns, and downstream bottlenecks in logistics.

Automatic detection and counting offer major benefits:

- Real-time visibility: Know exactly how many items of each type are present at any moment.

- Quality assurance: Identify missing or mis-shaped packages, labels or container types instantly.

- Reduced labour cost: Replace manual tallying and inspection with edge or cloud-based AI.

- Scalability: Deploy across lines, plants or product types with minimal retraining.

Introducing PackDet

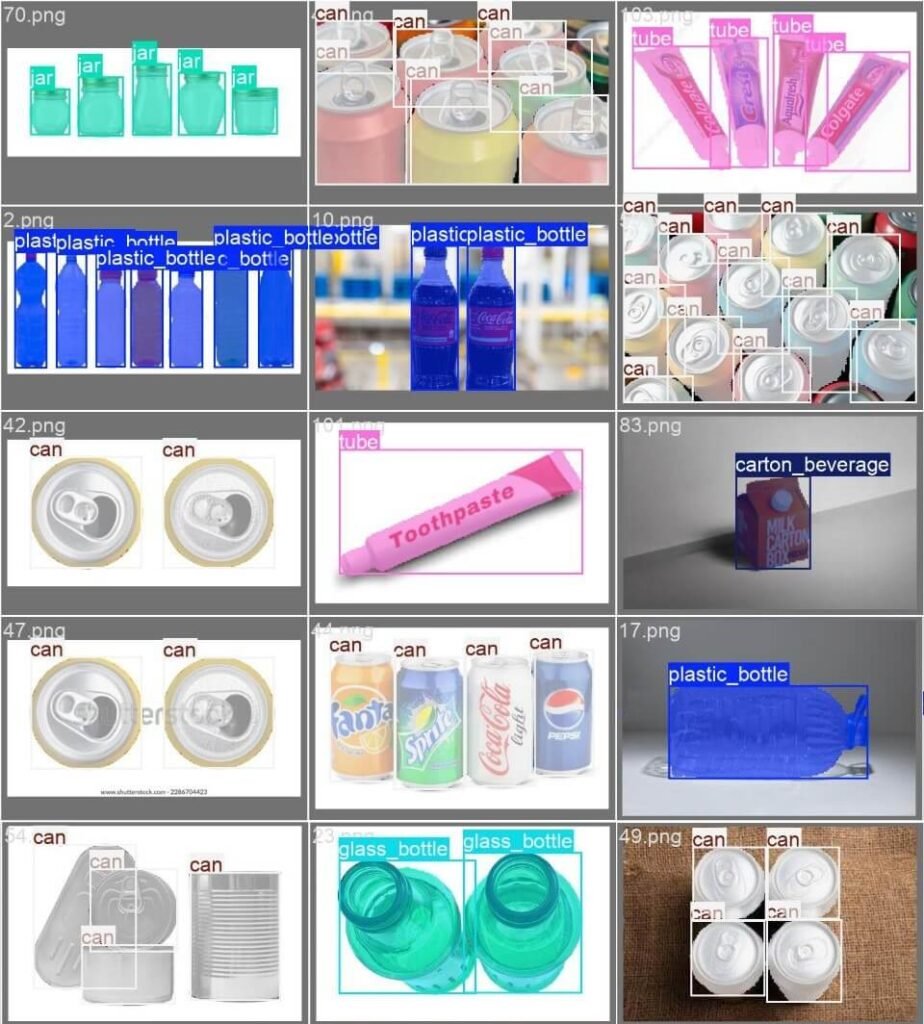

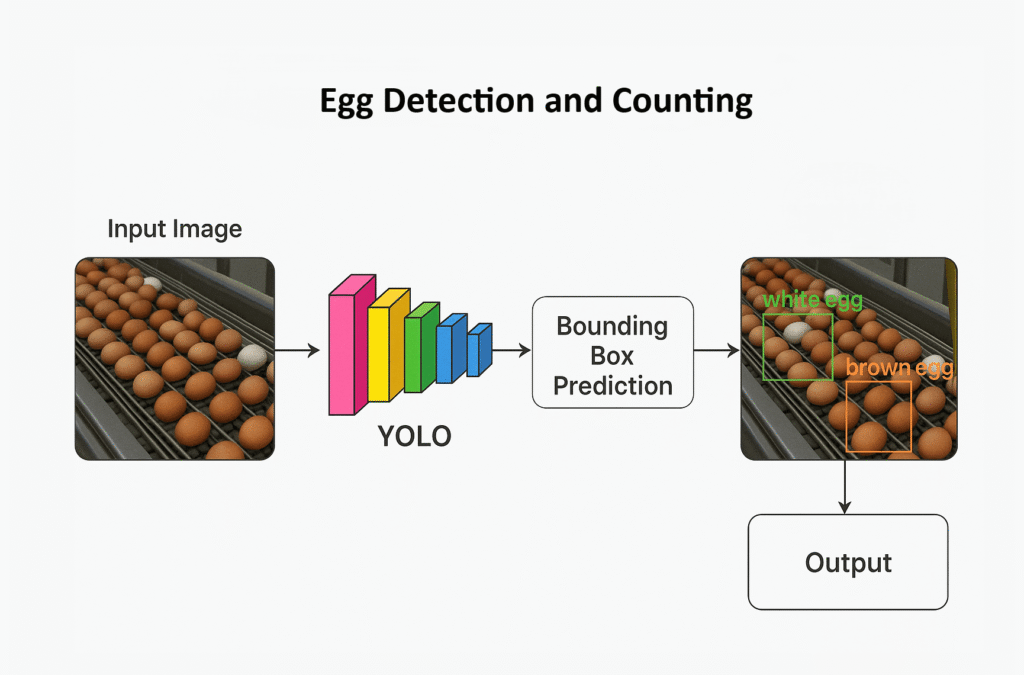

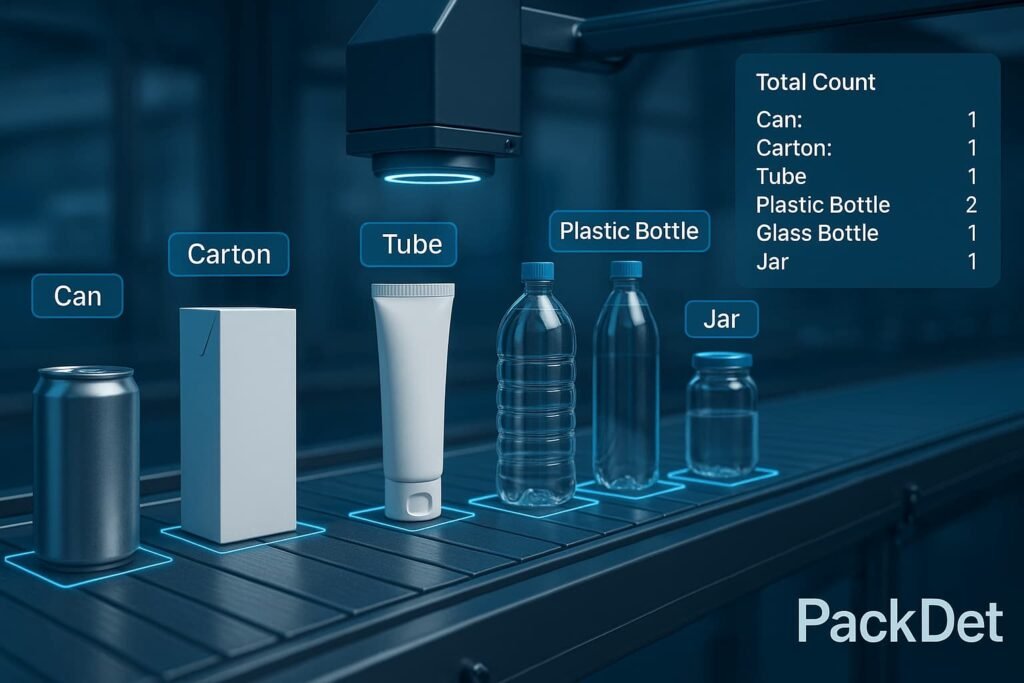

PackDet is an AI-driven detection and counting system tailored for packaging lines. It classifies and counts multiple packaging formats, e.g., cans, cartons, tubes, plastic bottles, glass bottles and jars, under real-world manufacturing conditions.:

Key features at a glance

- Multi-class detection: Recognises and counts diverse container types in one pass.

- High-speed conveyor support: Handles fast-moving belts and overlapping items.

- Edge/cloud deployment: Flexible architecture for on-premise or cloud-based inference.

- Analytics & reporting: Provides count metrics, error rates and visual overlays for operators.

- Easy integration: Compatible with existing camera systems, PLCs and MES (manufacturing execution systems).

PackDet Dataset

The custom dataset used to train and validate the package detection model is also available through the GitHub repository. It contains:

- Annotated images of different types of packages from different angles.

- Bounding box labels required for supervised learning.

- Edge/cloud deployment: Flexible architecture for on-premise or cloud-based inference.

- Diverse samples to ensure model robustness.

- Multiple overlapped objects in each image similar to real-world applications.

Using this dataset, you can retrain the model or extend it to new scenarios.

More about the dataset: PackDet

Use Cases

PackDet is designed for versatility across multiple industries, offering precise detection and counting of diverse package types.

- Beverage Industry: Detects and counts cans, plastic bottles, and glass bottles on high-speed conveyor belts.

- Food Packaging: Identifies cartons, jars, and pouches, ensuring accurate packing and reducing waste.

- Cosmetics Manufacturing: Recognizes tubes, bottles, and jars with reflective or glossy surfaces.

- Pharmaceutical Bottling: Differentiates plastic and glass bottles for batch tracking and compliance.

- E-commerce Fulfillment: Verifies mixed product packaging before shipment to prevent mispacks.

- Dairy & Juice Production: Counts cartons and bottles in real time for efficient supply monitoring.

PackDet adapts to any production environment, from automated filling lines to final packaging verification, delivering speed, precision, and actionable insights.

See It in Action

Want to see the Deep Package Detection and Counter in action? Try out the live demo where you can upload your own images and watch the model detect and count packages instantly.

👉Live Demo: Here

Open-Source and Ready to Use

This project is fully open-source and available on GitHub. You can run it locally, retrain the model on your own dataset, or integrate it into your own systems with minimal setup.